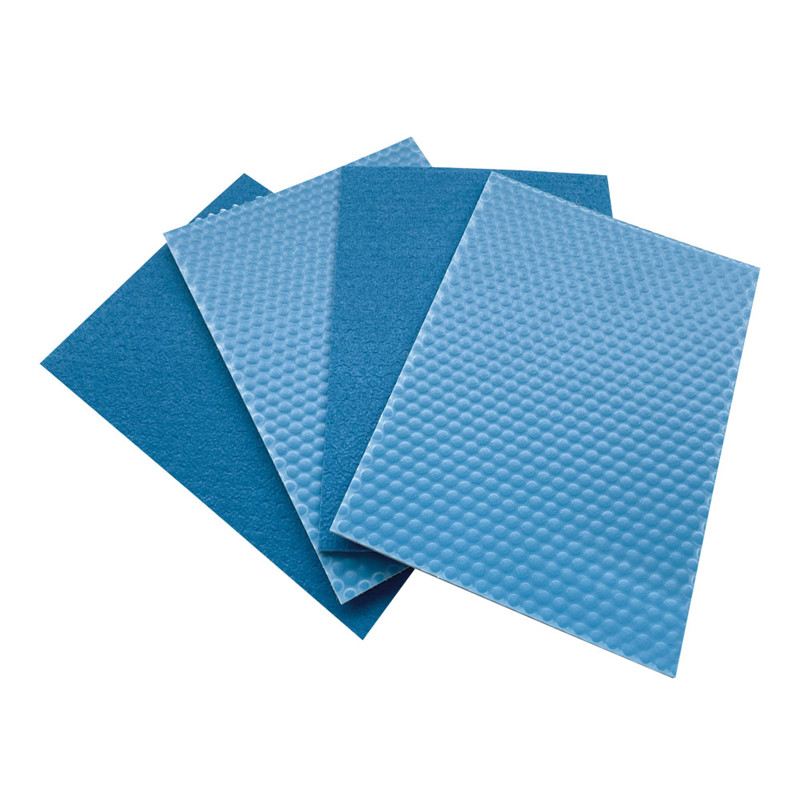

Supply Con-Pearl Structure Polypropylene PP Honeycomb Panels Plastic Honeycomb Panel

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for Supply Con-Pearl Structure Polypropylene PP Honeycomb Panels Plastic Honeycomb Panel, We welcome an prospect to do small business along with you and hope to have pleasure in attaching further particulars of our merchandise.

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for China Flame retardant Bubble Guard Sheet and PP Bubble Guard Sheet, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

Product description

The term “flame-retardant” is attributed to the inclusion of flame-retardant additives during the manufacturing process.These special chemical substances come into effect in the event of a fire, effectively suppressing the flame propagation speed, reducing flame temperature and intensity, thereby slowing down the spread of fire and providing valuable time for fire suppression and personnel evacuation.

Due to its outstanding fire-resistant performance, PP flame-retardant honeycomb panels find wide applications in fields that require high fire resistance. For example, in the aerospace industry, they are commonly used in the internal structures and cabin walls of aircraft to enhance fire safety. In railway transportation, these panels might be used in the interior design of train carriages to improve the fire safety of trains. Additionally, they are widely employed in the field of building decoration, such as for walls, ceilings, and other areas, to raise the overall fire rating of buildings.

Details

01. SHOCK RESISTANCE

Flocked honeycomb boards offersuperior product protection byreducing damage caused byimpacts and collisions.

02. LIGHTWEIGHT

They reduce transportationvehicle load weight, improvingspeed and lowering costs.

03.FLAME RETARDANT

Add flame-retardant masterbatchto the product, achieving VO flameretardancy and immediate self-extinguishing.”

04.GOOD SOUNDINSULATION

PP honeycomb panels cansignificantly reduce the diffusionand propagation of sound.

Features

- 1. Waterproof and easy to clean, Moisture resistance, Excellent weather ability.

- 2. Custom Color is available.

- 3.Food contact packing,Virgin and Recycled materials.

- 4.Environmental friendly, recycled use,

application

Flame-retardant honeycomb panel is an environmentally friendly material with excellent flame retardancy achieved through special treatment. Its internally air-filled closed chambers endow it with superior sound insulation, moisture resistance, shock resistance, and antistatic properties. Widely used in construction, logistics, and children’s vehicles, it provides reliable safety for buildings and personnel. However, to ensure its flame retardancy, it is necessary to install and maintain it according to regulations.

Flame-retardant honeycomb panel is an environmentally friendly material with excellent flame retardancy achieved through special treatment. Its internally air-filled closed chambers endow it with superior sound insulation, moisture resistance, shock resistance, and antistatic properties. Widely used in construction, logistics, and children’s vehicles, it provides reliable safety for buildings and personnel. However, to ensure its flame retardancy, it is necessary to install and maintain it according to regulations.