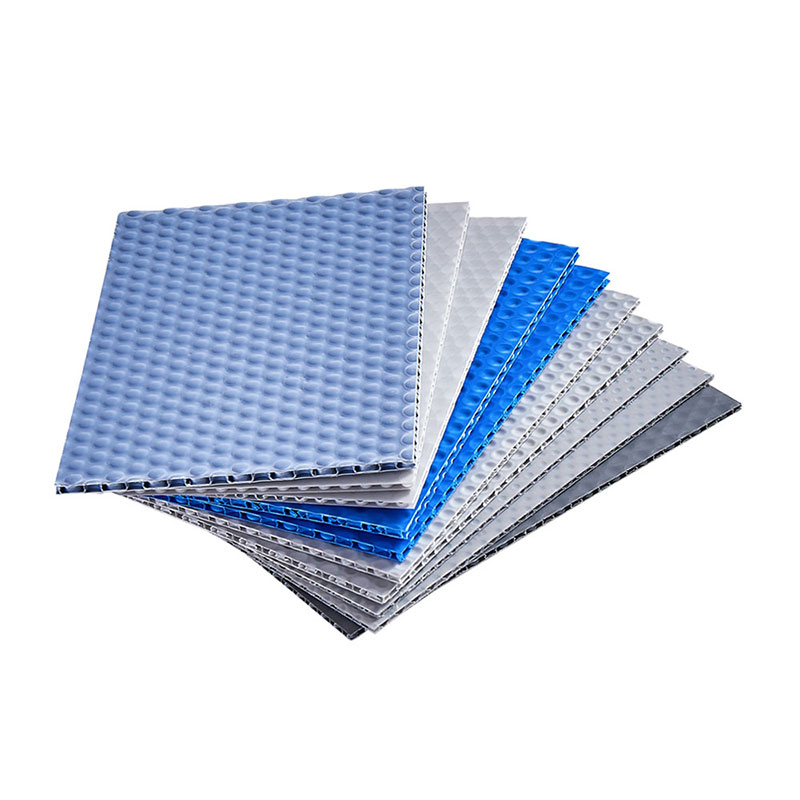

PP Honeycomb Bubble Guards Sheets durable Sandwich panel

Product details

Foremost, the polypropylene honeycomb panel boasts an exceptional balance of lightweight and high strength. The honeycomb structure efficiently utilizes material to achieve maximum strength, rendering the panel both lightweight and sturdy. This characteristic is particularly valuable in weight-sensitive domains, such as aerospace and automotive manufacturing, where it aids in reducing overall weight without compromising structural integrity.

Furthermore, the honeycomb structure is responsible for the panel's exceptional thermal insulation capabilities and low thermal conductivity. The air-filled cells within the honeycomb design act as effective barriers to heat transfer, making the panel a sought-after solution for applications requiring superior insulation. This capability positions the panel as an ideal choice for insulation in building construction, enhancing energy efficiency in walls, roofs, and floors.

Moreover, the polypropylene honeycomb panel's resilience against corrosion further contributes to its versatility. The inherent chemical resistance of polypropylene enables its application in environments prone to corrosion, including chemical industries and marine settings.

The panel's malleability and ease of processing add to its appeal, allowing for a range of fabrication processes such as cutting, shaping, and bonding. This adaptability facilitates tailoring the panel to specific needs, enabling its integration into diverse products and designs.

In light of its environmentally friendly attributes and multifaceted benefits, the polypropylene honeycomb panel finds extensive use in industries spanning aerospace, automotive manufacturing, construction, and packaging. Its utility extends beyond structural components, encompassing applications as varied as sound and thermal insulation materials, as well as interior components. From its exceptional mechanical properties to its functional versatility, the polypropylene honeycomb panel stands as a testament to modern engineering ingenuity, paving the way for innovation and progress in an array of fields.

Features

1.Lightweight and strong.

2. Corrosion-resistant.

3. Good thermal insulation.

4.Easy to process and print.

5. Environmentally friendly and recyclable.

6. Resistant to fungal growth and easy to clean.

7. Waterproof and moisture-proof

application